The shift toward sustainable packaging

Consumers are increasingly favoring packaging solutions that meet "clean" and "green" standards. A Nielsen report highlights that environmental considerations now rank among the top five factors influencing purchasing decisions.

As sustainability takes center stage, the use of advanced technologies to develop lightweight, durable, and recyclable plastic products is becoming a priority. Many companies are revising production standards, integrating recycled materials, and implementing plastic reduction strategies to extend product lifecycles and minimize waste.

This shift is particularly noticeable in the food, personal care, and beverage industries across North America and Europe, where businesses are increasingly adopting sustainable plastic packaging. The trend reflects both corporate social responsibility and the growing demand from environmentally conscious consumers.

MuCell® Technology: optimizing weight while maintaining durability

With nearly 40 years in the Vietnamese plastics industry, Duy Tan (a member of SCGP) has focused on sustainable production and circular economy initiatives. In collaboration with Trexel, a leader in foaming technology, Duy Tan has introduced a lightweight bottle solution utilizing MuCell® microcellular foam technology, offering advantages for both manufacturers and consumers.

By incorporating foaming technology, Duy Tan’s lightweight bottle achieves up to a 20 per cent weight reduction while maintaining key properties such as impact resistance, durability, and topload strength. The reduced weight lowers transportation costs and carbon emissions, supporting environmental goals.

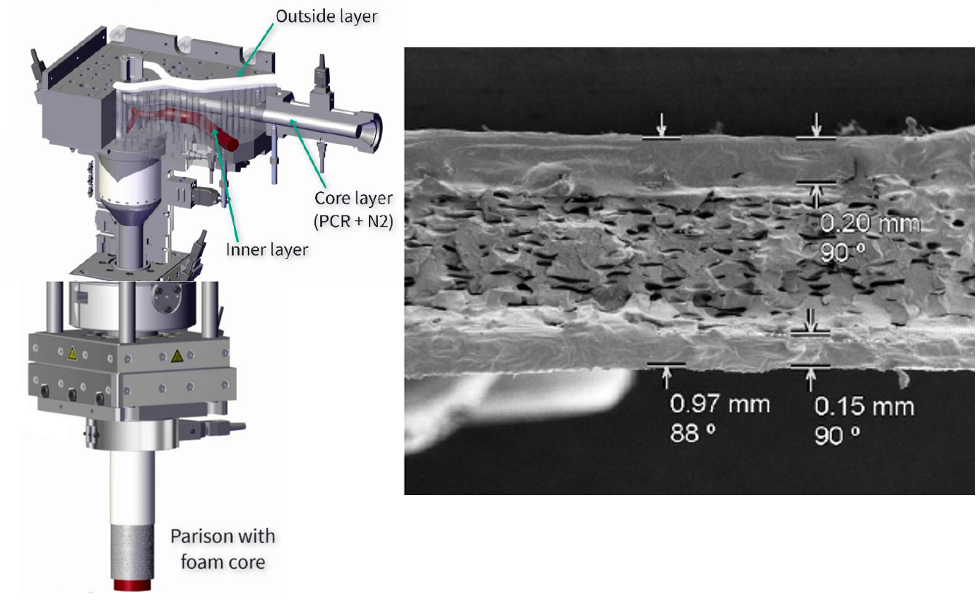

According to the manufacturer, MuCell® technology works by introducing an inert gas, typically nitrogen, into the plastic manufacturing process, creating microcellular structures that reduce material density without compromising performance. This method eliminates the need for additional waxes or stearates that can affect impact strength or cause mold buildup. Consistent nitrogen delivery, ensured by Trexel’s B-Series pumping unit, allows for precise and reliable foaming across different product lines.

A notable advantage of this technology is its compatibility with post-consumer recycled (PCR) plastic. Duy Tan’s lightweight bottles can incorporate up to 50 per cent PCR material in the core layer, reducing reliance on virgin plastic and helping preserve natural resources. The fully recyclable design further contributes to reducing plastic waste and landfill pressure, an important factor for businesses prioritizing sustainability.

Additionally, the lightweight structure reduces raw material consumption, leading to cost savings in production. Lower material expenses and reduced transportation costs make this technology a compelling option for manufacturers seeking efficiency improvements.

A representative from Duy Tan described the lightweight bottle with MuCell® foaming technology as a significant development in plastic manufacturing. The collaboration with Trexel marks a step forward in foaming technology advancements. “With its ability to reduce weight, maintain strength, incorporate PCR materials, and be fully recyclable, this product offers a sustainable solution for the future of packaging businesses. Additionally, it has high applicability across various industries, including chemicals, cosmetics, and household products, contributing to carbon footprint reduction, optimizing production costs, and providing consumers with an eco-friendly alternative.”

Advancing sustainable packaging

Beyond lightweight bottles, Duy Tan continues to explore new solutions for international-standard, eco-friendly, and health-conscious packaging, in line with its "Sustainable Packaging Production and Usage" strategy.

Duy Tan’s products meet high recyclability standards, such as RRC (Recyclable, Reusable, or Compostable), with certain items, like pallets and plant pots, made entirely from recycled materials. The company also adheres to ISCC standards for carbon management and supply chain sustainability, as well as SCG Green Choice criteria, which emphasize reduced plastic consumption and increased recycled content.

Collaborating with global brands like Nestlé, Motul, and Muji, Duy Tan has introduced PCR/rPET and rPP recycled plastic bottles, optimized soy sauce and oyster sauce bottle caps to reduce plastic use, and developed tethered caps for bottled water and carbonated soft drinks—designed to simplify sorting and recycling.

The company is also actively researching biodegradable (BIO) plastics, aiming to expand its portfolio with environmentally responsible materials in the near future.

These efforts reinforce Duy Tan’s role within SCG Packaging (SCGP), ASEAN’s leading provider of integrated packaging solutions, while aligning with the global push for sustainability.

Hotline: ( 84-28) 3876 2222

Email: info@duytan.com

Website: https://duytan.com/

Fanpage: https://www.facebook.com/DuyTanPackaging

Google translate

Google translate