It often starts with a simple question during a factory visit in Vietnam: “Why are there so many workers on this line?”

Foreign guests, especially those familiar with factories in Europe or East Asia, are often surprised. In many Vietnamese manufacturing plants, tasks that are fully automated elsewhere are still done by hand. Rows of workers assemble parts, label products, or manage packing manually. It’s not unusual to hear the explanation: “Labor here is still affordable.”

For decades, this has been Vietnam’s competitive edge. A young, abundant workforce powered the country’s rise as a manufacturing hub. Products “Made in Vietnam” may not have been high-tech, but they were made quickly and cost-effectively.

But today, a quiet shift is happening, one that’s beginning to reshape shop floors and business models across the country.

Drivers behind automation adoption

- Workforce shortages & rising labor costs

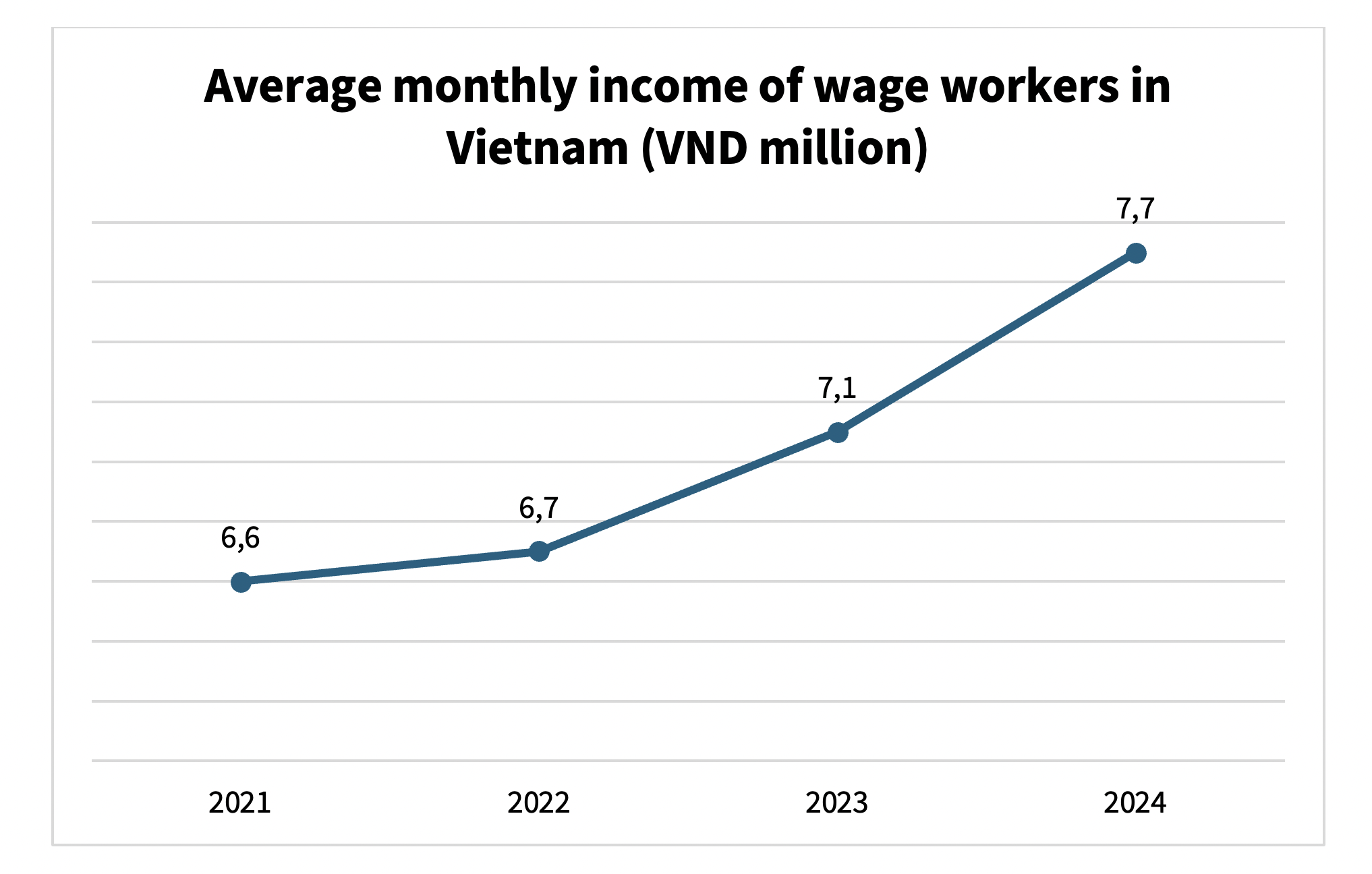

Vietnam has historically been recognized for its competitive labor costs, attracting numerous manufacturing investments. However, recent data indicates a steady rise in wages due to economic growth and an increased demand for skilled workers. According to the National Statistics Office (Ministry of Finance), the average monthly income of Vietnamese wage workers reached VND7.7 million ($308) in 2024, marking an 8.6% increase from 2023. The manufacturing sector experienced an even steeper increase of 12% income growth during this period.

This rise in labor costs is further intensified by labor shortages in many of Vietnam’s industrialized regions, such as Binh Duong and Dong Nai. When driving through industrial parks in this area, guests will notice red signs in front of many factories advertising jobs that can only be filled with difficulty. The successful manufacturing business is leading to growth pains in the form of labor shortages that employers must address.

These labor trends are prompting manufacturers to seek automation solutions to maintain cost efficiency and competitiveness.

- Increasing quality demands

When thinking about typical Vietnamese exports, many international observers may still have clothing, footwear, and agri-produce in mind. While these still are important export industries, the most important trade goods of the country are electronics.

As Vietnam deepens its integration into global supply chains, international clients are setting increasingly higher quality standards in terms of precision engineering demand. These make advanced automation essential. By adopting these technologies, Vietnamese manufacturers can enhance product quality, boost efficiency, and strengthen their position in the global value chain.

Vietnam’s mold manufacturing sector is vital for industries like automotive and electronics. While full automation is often not feasible due to single-piece production, certain steps, such as CNC machining or quality control, can still benefit from targeted automation.

Beyond manufacturing, automation is also transforming Vietnam’s logistics sector. The integration of automated warehouse systems has not only improved operational efficiency but has also created high-tech jobs, further reinforcing the country’s industrial capabilities and readiness for global competition.

Automation as the solution

Automation has been a major force behind Germany's industrial growth, crucial in economic value creation. In 2024, the country's industrial automation sector contributed 19.7% to the total manufacturing GDP, according to the German Federal Statistical Office (Destatis). With a traditionally larger industrial sector than other major EU economies, Germany exemplifies how technology adoption drives productivity and fosters innovation.

For Vietnam, automation presents an opportunity to accelerate its industrial development. By implementing smart manufacturing solutions, Vietnam can enhance operational efficiency, reduce errors, and achieve greater production scalability. This shift will support the country’s goal of becoming a high-tech manufacturing hub, as outlined in Resolution No. 23/NQ-TW, which aims for the industry to contribute over 40% of GDP by 2030.

Vietnam’s efforts toward automation

Vietnam is accelerating its Industry 4.0 agenda through strategic initiatives designed to drive digital transformation and technological innovation.

One key initiative is the National Digital Transformation Program, launched in June 2020, which outlines ambitious goals for 2025 and a long-term vision for 2030. The program prioritizes expanding broadband coverage, increasing electronic payment adoption, and integrating digital platforms across industrial parks and export processing zones to enhance efficiency and competitiveness.

Additionally, the government is implementing industrial policies that emphasize automation in priority sectors such as electronics, automotive, and logistics. To attract investment in these high-tech industries, businesses can benefit from preferential tax rates, tax holidays, and land rent exemptions, making Vietnam an increasingly attractive destination for technology-driven manufacturing.

Despite these proactive efforts, challenges remain. A significant skills gap in technical expertise continues to hinder the adoption of advanced technologies. Moreover, the high initial costs of automation and the complexities of integrating new systems with existing infrastructure pose additional barriers for businesses.

To overcome these challenges, collaboration with international automation leaders can play a crucial role. Through knowledge transfer, technical support, and investment, these partnerships can help Vietnamese enterprises successfully navigate the transition to Industry 4.0, strengthening their position in the global value chain.

Factory automation – made in Germany symposium

Supporting the automation transition in Vietnam, the Factory Automation – Made in Germany Symposium serves as a premier platform for Vietnamese businesses to explore world-class German expertise in industrial automation. Organized by the Delegation of German Industry & Commerce in Vietnam (AHK Vietnam) in collaboration with leading German technology providers, this event highlights groundbreaking solutions that will shape the future of Vietnam’s manufacturing landscape.

This event will feature leading German automation providers, offering Vietnamese businesses the chance to explore innovative solutions for smart manufacturing. Some of the key participating companies include Bosch Rexroth Vietnam, Beckhoff Automation, Baumer Group, Fibro Rundtische, TRUMPF Vietnam, Wuerth Industry Service Vietnam, and SEW EURODRIVE Vietnam.

Unlocking new opportunities in factory automation

The symposium, organized by AHK Vietnam, offers a valuable platform for Vietnamese businesses to enhance their production capabilities through advanced automation. The event will showcase state-of-the-art technologies designed to improve efficiency, reduce costs, and drive competitiveness in an increasingly digitalized manufacturing landscape.

Participants will have the opportunity to engage directly with leading German technology providers, gaining insights into best practices for smart manufacturing and Industry 4.0 integration.

As Vietnam continues its journey toward industrial automation and smart manufacturing, collaboration with trusted and experienced technology providers is crucial. German companies, with their reputation for precision engineering, innovation, and reliability, are well-positioned to drive this transformation.

The Factory Automation – Made in Germany Symposium is more than just an event – it is a gateway to the future of smart manufacturing in Vietnam. Don’t miss this opportunity to explore groundbreaking automation solutions and build lasting business connections.

Google translate

Google translate